The purpose of the Infrared Thermography test is to identify, isolate and document abnormally warm or cool connectors, conductors, or components that may be a potential problem in electrical systems. Many dangerous conditions cannot be seen by the human eye and this test can find electrical system touble spots before they become disastrous.

Problems that arise can be caused by:

- Loose or deteriorated connections

- Short circuits

- Overloads

- Load imbalances

- Faulty, mismatched or improperly installed components

Some of the electrical equipment Titan Power’s Certified Thermographer inspects:

- Category III transformers

- Relay panels

- Fuse disconnects

- Circuit breakers

- Electrical switchgear

- Fans for bearing degradation

Important UPS components such as:

- AC capacitor banks

- DC capacitor banks

- Harmonic filters for capacitor degradation

- Batteries to detect thermal runnaway

Three ways to start your Infrared Thermography Preventative Maintenance:

- Add Infrared Thermography testing to your existing Maintenance Agreement with Titan Power.

- Start a separate Maintenance Agreement for Infrared Thermography testing.

- Have Infrared testing completed as a One-time service or on an As-needed basis.

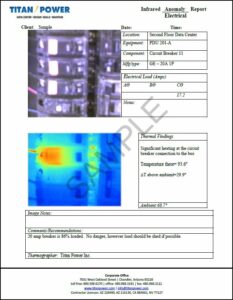

Titan Power utilizes this infrared imaging system along with powerful software designed to provide a fast and effective means of identifying potential power problems in electrical and mechanical equipment, refractory and insulation materials. This information is compiled into a comprehensive report using easily interpreted text with the infrared image and a visible light reference. From the report, preventative or corrective repairs can then be scheduled on a priority basis.

Contact us for more information on Infrared Thermography testing.

Infrared Thermography FAQ

Q: Can infrared Thermography be used to find overloaded circuits within a data center?

A: Yes, Infrared Thermography is one of the best preventative maintenance tools for identifying and correcting overloaded circuits or bad connections before they cause an outage. We recommend Infrared Thermography be formed on a semi-annual basis. This can be added into the contract,